Poly Solar Panel

Categories

Solar Panel

Solar Power System

Solar Cell

Hot products

Your leading supplier of Baoding Dongliang New Energy Technology Co., Ltd

Baoding Dongliang New Energy Technology Co., Ltd. is a high-tech enterprise focusing on the integrated application of photovoltaic products, committed to the design, research and development, production and sales of photovoltaic panels, solar power generation systems and other products.

Why Choose Us?

01/

Quality

We provide our customers with high-quality products, and we have applied for IEC, CE, ISO and other related certifications for our products.

02/

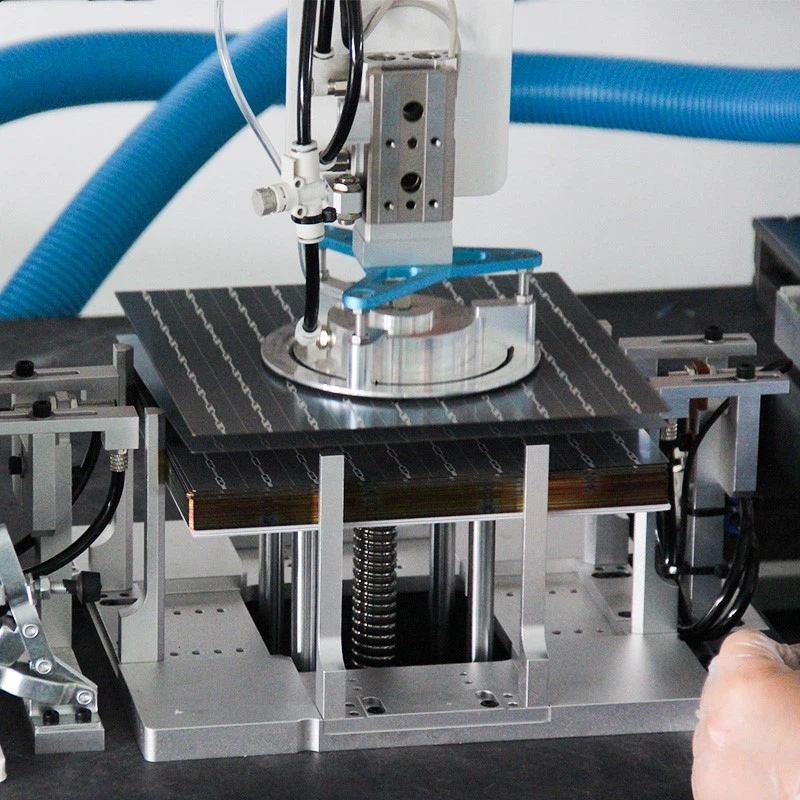

State-of-the-art equipment

We have 1 SMT production line, 2 photovoltaic production lines, 1 lithium battery pack line and other modern production lines.

03/

With 11 years of experience, we can develop, produce and sell any new energy-related products, modules, inverters, controllers, batteries, brackets, cables and other complete solutions according to your needs;

04/

The company has enough practice in the application of photovoltaic-related products, including grid-connected photovoltaic power generation, off-grid photovoltaic power generation, BIPV projects, wind-solar complementary projects, and application-oriented power supply systems (monitoring power supply, sensor power supply, solar street lights, etc.);

What is Poly Solar Panel?

Polycrystalline solar panels have blue-hued PV cells with straight edges. They have a lower efficiency compared with monocrystalline cells, which means you need more panels to reach the same power output. However, polycrystalline panels also have a lower price, since their manufacturing process is simpler. Polycrystalline panels are very durable, but they tend to last slightly less than monocrystalline panels. They are also affected more by high temperatures, which reduces their productivity on the hottest days.

Benefits of Poly Solar Panel

Cost-Effectiveness

One of the primary advantages of polycrystalline solar panels is their cost-effectiveness. Compared to other types of solar panels, such as monocrystalline panels, polycrystalline panels typically have a lower production cost. This cost advantage stems from the manufacturing process, which involves melting together silicon fragments to form a solid structure. As a result, polycrystalline panels offer an attractive option for large-scale solar installations where maximizing cost savings is a priority. By choosing polycrystalline panels, stakeholders can achieve significant upfront savings without compromising on performance.

Efficiency and Performance

While polycrystalline solar panels may have a slightly lower efficiency compared to monocrystalline panels, recent advancements in production techniques have narrowed the efficiency gap. Polycrystalline panels are now capable of delivering respectable levels of performance, making them a viable option for various applications. In regions with ample sunlight, polycrystalline panels can generate sufficient electricity to meet both residential and commercial energy needs. Additionally, the performance of polycrystalline panels can be optimized through proper system design, orientation, and maintenance practices, ensuring reliable energy production over the panel’s lifespan.

Durability and Longevity

Polycrystalline solar panels are renowned for their durability and longevity. Constructed from sturdy silicon fragments, polycrystalline panels are resistant to wear and tear caused by environmental factors such as temperature fluctuations, moisture, and UV exposure. With proper installation and maintenance, polycrystalline panels can withstand harsh weather conditions and continue to operate efficiently for decades. This durability not only ensures a reliable energy supply but also minimizes the need for frequent replacements, reducing overall lifecycle costs and environmental impact.

Versatility and Adaptability

Another advantage of polycrystalline solar panels is their versatility and adaptability to diverse installation environments. Polycrystalline panels can be seamlessly integrated into various architectural designs, whether mounted on rooftops, ground-mounted arrays, or incorporated into building facades. This flexibility in installation options allows for optimal utilization of available space and sunlight exposure, maximizing energy production potential. Additionally, polycrystalline panels are compatible with a wide range of mounting systems and inverters, making them suitable for both residential and commercial applications.

Environmental Sustainability

Polycrystalline solar panels contribute to environmental sustainability by harnessing clean, renewable energy from the sun. By displacing fossil fuel-based electricity generation, polycrystalline panels help reduce greenhouse gas emissions and mitigate climate change. Furthermore, the manufacturing process of polycrystalline panels continues to improve in terms of energy efficiency and resource conservation, further enhancing their environmental credentials. With growing emphasis on sustainability and carbon neutrality, polycrystalline solar panels play a crucial role in advancing the transition towards a greener energy future.

Schedule regular cleaning

To keep solar panels in good condition, you must clean them at least twice a year: one at the end of fall and another at the start of winter. If they’re installed in an area with a high dust, pollen, or dirt concentration, it’s recommended to clean them more often, for example every three months.

Choose the right time

The maintenance and cleaning of solar panels must be carried out during the early hours of the morning, when the panels are fresher. Cleaning them when they are still warm or exposed to direct sunlight may be counterproductive, as the combination of heat and cold water can generate thermal stresses and damage the equipment. Avoid when windy, rainy, or snowy.

Schedule regular cleaning

If you haven’t detected any problems, you can start with the cleaning. Make sure you remove any kind of dirt, dust, or debris that may affect the performance of the solar panels.

Carry out a visual inspection

Before starting, carry out a visual inspection of the solar panels to identify possible damages such as cracks, breaks, or loose connections. If you detect any problems, contact a professional to carry out the necessary checks and repairs.

Dry the panels

You can let the solar panels air-dry, or you can use soft cloths. The most important thing is that no water residue remains that may affect the efficiency of the panels.

Monitoring

For proper maintenance, record the date you clean the solar panels, and schedule the next one. This will allow you to properly monitor and maintain the installation in optimal conditions.

Components of Poly Solar Panel

Toughened glass

Its role to protect the main power generation (such as solar cells), the selection of light is required:

(a). Light transmittance must be high (generally more than 91%);

(b). Super white tempered

EVA

It’s used to bond the fixed glass and the main power generation (such as solar cells).

The merits of transparent EVA material directly affect the life of the components exposed EVA in the air is easy to aging yellow, thus affecting the transmittance of the components, Thus affecting the quality of power generation components in addition to the quality of EVA itself.

The component manufacturers laminate process is also very large impact, such as EVA glue degree does not meet the EVA and toughened glass, backplane adhesive strength is not enough, will lead to premature aging EVA , Affect the component life.

Battery

The main role of the battery is to generate electricity, the main power generation market is the mainstream of crystalline silicon solar cells, thin film solar cells.

Backplane

It’s role is sealing, insulation, waterproof (generally use TPT, TPE and other materials must be resistant to aging, most component manufacturers are warranty 25 years, tempered glass, aluminum alloy generally no problem, the key is with the backplane and silicone Is it able to meet the requirements?

Aluminum protective laminate

It’s from a certain seal, support role

Junction box

It protects the entire power generation system, play the role of current transfer station, if the components short-circuit Junction box automatically disconnect the short circuit to prevent burnout The entire system junction box is the most critical choice of diodes, according to the battery Different types, the corresponding diode is not the same.

Silicon glue

Silicone rubber seal, used to seal components and aluminum frame, junction boxes and components Some companies use double-sided tape, foam instead of silica gel.

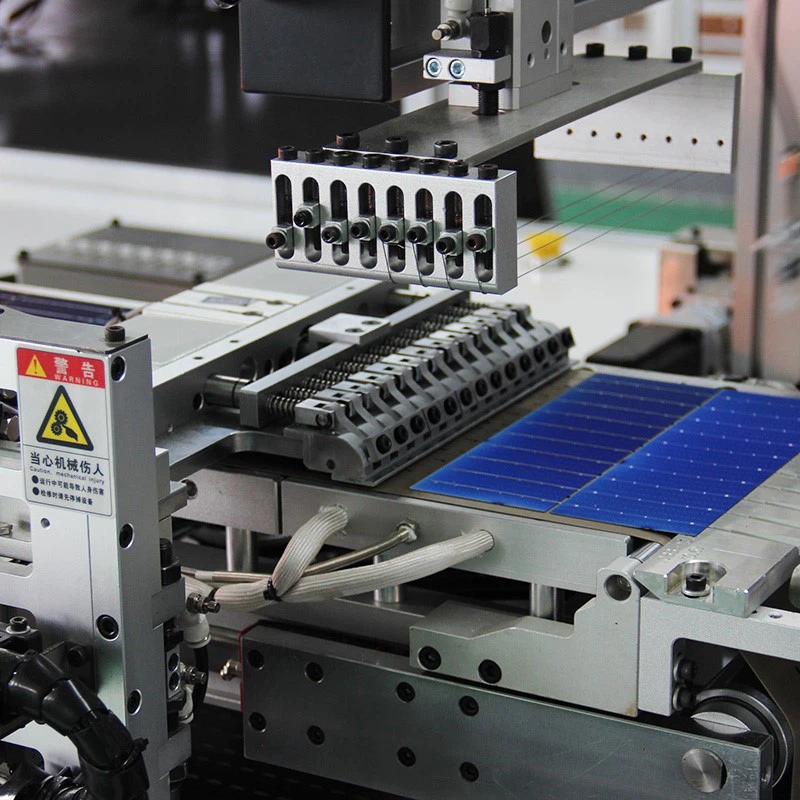

Process of Poly Solar Panel

1.Build solar silicon cells that are either , meaning positively or negatively charged. P-type silicon cells were the traditional structure of solar cells. A p-type silicon cell is built on a positively charged base, meaning the bottom layer is mixed with boron and the top layer is mixed with phosphorus.

But the n-type cell is built oppositely, with the phosphorus serving as the base. The main difference is that n-type cells offer more efficiency and they are not affected by light-induced degradation, or reduction in output when exposed to extreme sunlight.

Solar cells are made with crystalline silicon that is melted and mixed with gallium or boron to form wafers. Phosphorous is then added to the silicon, and along with the gallium or boron, these substances give silicon its electrical capability.

The silicon ingot is then cut into thin sheets and an anti-reflective coating is applied to capture the sunlight instead of reflecting it away from the panels. Thin lines are then cut into the cells to capture and move the electrical current within the cell.

The solar cells become semiconductors of electricity which is generated by the photovoltaic effect, when the sunlight’s photons are absorbed, electrons then drift within the solar cells to create energy.

Monocrystalline solar panels are formed from one silicon fragment but for polycrystalline panels, many silicon fragments are melted together in one large sheet to form the silicon wafers for the solar panel.

2.Solder solar cells together to form one panel, usually 60 or 72 solar cells form one panel.

3.Install the backsheet which protects the bottom of the solar cells.

4.Install glass front. This allows light to filter through to the solar cells and provides a protective layer.

5.Seal a metal frame around the panel with silicon to fuse all of the layers together.

6.Install the junction box which protects the solar panel’s electrical wires from damage.

7.Test solar panel for quality and strength before shipping out for use.

How to Maintain Poly Solar Panel

1.Solar panels require very little maintenance, especially if they are on a tilt, as rain can wash away any debris.

2.It is generally recommended that you perform solar panel cleaning between two and four times per year. Take extreme care when cleaning.

3.Clean from the ground, as climbing around on your roof can be dangerous. Use a soft-bristled cleaning brush and a non-abrasive cleaner. Be sure to clean the panels early in the morning before they get too hot from the sun; cold water and hot panels do not mix!

Polycrystalline Solar Panel Working Principle

These solar panels are made of multiple photovoltaic cells. Each cell contains silicon crystals which makes it function as a semiconductor device. When the photons from the sunlight fall on the PN junction (junction between N-type and P-type materials), it imparts energy to the electrons so that they can flow as electric current. Here, P-type materials are deficient in electrons while N-type materials have an abundance of electrons. Two electrodes are connected to the PV cells. The electrode that is on the top surface contains small wires while the electrode on the bottom is a foil-like conductor.

Factors That Could Affect the Useful Life of Solar Panels

Temperature

The efficiency of solar panels that are exposed to high temperatures may decrease over the years. Increased temperature causes thermal stress on materials, so photovoltaic cells may experience a faster degradation process.

Shade

If the solar panels are partially shaded by trees, buildings, or other objects, the performance of the entire system could be affected. This is because the panels in series are connected to each other, so the performance of one panel affects the others.

Dirt

Dirt, such as dust, leaves, or other debris acts as a barrier that obstructs sunlight and decreases efficiency. If not cleaned regularly, it could stick to the surface, which could cause permanent damage.

Monocrystalline Vs. Polycrystalline Solar Panels: Key Differences

FACTOR

Silicone Arrangement

Cost

Appearance

Efficiency

Lifespan

Temperature Coefficient

MONOCRYSTALLINE SOLAR PANELS

One pure silicon crystal

More expensive

Panels have black hue

More efficient

25-40 years

Lower temperature coefficient, making them more efficient in heat

POLYCRYSTALLINE SOLAR PANELS

Many silicon fragments melded together

Less expensive

Panels have blue hue

Less efficient

20-35 years

Higher temperature coefficient, making them less efficient in heat

How Is Blockchain Technology Used in the Solar Industry?

Blockchain technology is a distributed digital ledger system that can enable secure, transparent, and decentralized energy trading in the solar industry. It allows peer-to-peer energy trading between consumers, producers, and system operators with no intermediaries, facilitating more efficient and reliable energy transactions.

Blockchain technology can enhance the transparency and traceability of solar energy transactions, promote the use of renewable energy sources, and enable the integration of distributed energy resources. It can also facilitate microgrids, improve operations and maintenance, and reduce transaction costs.

Ground-Mounting? How to Make as Much Electricity as Possible

Your roof probably doesn’t match the perfect azimuth and angle for maximum solar production, so the panels won’t produce as much energy as they would under ideal conditions. But it’s the cheapest, easiest way to get a good-enough solar setup onto your home.

If you can put solar near your home with a ground-mounted system, then you can set up a perfectly optimized system that generates the maximum possible energy per panel. Here’s how to do it.

The perfect direction: It isn’t always perfectly south (180 degrees)—it can actually vary by a few degrees to the east or west.

The perfect angle: A common rule of thumb is that solar panels are most productive when they’re installed at an angle to match the local latitude. That’s true “if every day is sunny,” as a SETO spokesperson told us. “But on cloudy days, the optimal angle is zero,” because the clouds diffuse the sunlight throughout the entire sky. Since most parts of the US get a mix of sun and clouds, the most productive angle is actually flatter than the angle of latitude.

With the perfect azimuth and tilt, you’ll likely squeeze out 1-2% more energy over the course of a year than you would if you set up your ground-mount system facing due south, tilted to match the local latitude.

Our Factory

At present, the company has more than 200 employees, including 20 R & D technicians, and has more than 10,000 production workshops, 1 SMT production line, 3 photovoltaic production lines, 2 lithium battery pack line and other modern production lines. The annual production capacity of photovoltaic modules reaches 15 megawatts.

Our Certificate

FAQ

Q: Which is better, a solar panel mono or poly?

A: Polycrystalline panels have lower efficiency rates typically in the 13-16% range. Monocrystalline panels have higher efficiencies in the range of 15-20%. Because of the lower efficiency rate they are not as space-efficient since they produce less power per square foot.

Q: Can you mix monocrystalline and polycrystalline solar panels?

A: You can mix polycrystalline with monocrystalline solar cells, but it’s not recommended because of the different electrical characteristics the other cells give each panel. If you’re interested in mixing them due to a particular circumstance, it’s best to contact an electrician or professional installer.

Q: How can you tell if a solar panel is polycrystalline or monocrystalline?

A: Polycrystalline solar panels have blue cells made of multiple silicon crystals, and they are less efficient but more affordable. Monocrystalline panels have black cells made of single crystals, and they offer a higher efficiency at a higher price.

Q: How long do poly solar panels last?

A: 25 To 35 years

However, your panels can last longer than the manufacturer’s 25-year warranty with regular maintenance. Polycrystalline panels can last 25 to 35 years, while monocrystalline panels can last up to 40 years. Although panels can last for decades, they lose their efficiency over time.

Q: Which is cheaper monocrystalline or polycrystalline?

A: Monocrystalline models are the most efficient solar panels for residential installations (17% to 22% efficiency, on average) but are a bit more expensive than their polycrystalline counterparts (about $1 to $1.50 per watt before installation).

Q: Do solar panels charge faster in series or parallel?

A: Series

By wiring in parallel, your panels must run at a higher consistency to maintain the minimum voltage required. This means that, in general, series wiring may mean faster charging times.

Q: Is it better to have more amps or volts from solar panels?

A: The lower the voltage, the higher the Amps, and the faster current flowing out of the panel, and the faster a battery will charge.

Q: What are the advantages of polycrystalline solar panels?

A: With an energy efficiency rate of 13% to 15%, polycrystalline solar panels are one of the cheapest solar energy systems on the market. Since these solar panels require less energy to function, they are cost-effective too.

Q: Why are solar panels blue?

A: Solar panels appear blue because of the type of silicon (polycrystalline) utilized in a certain set of solar panels. The blue tint is primarily owing to an anti-reflective coating, which improves the solar panels’ absorption capacity and efficiency.

Q: Are half-cut solar panels better?

A: Half-cut solar cells perform better than traditional solar panels due to the higher number of cells and upgraded series wiring within the panel. Half-cut solar cells are typically higher-wattage than traditional panels, but they are more expensive and challenging to manufacture.

Q: What is the new more efficient solar panel?

A: Scientists at the University of Surrey have built a new kind of solar panel with two faces, both of them pretty. Their flexible perovskite panels have electrodes made of tiny carbon nanotubes. These can generate more power with greater efficiency and at a cost 70% lower than existing solar panels.

Q: What is the life expectancy of a polycrystalline solar panel?

A: Polycrystalline panels can last 25 to 35 years, while monocrystalline panels can last up to 40 years. Although panels can last for decades, they lose their efficiency over time.

Q: Are polycrystalline solar panels any good?

A: Polycrystalline solar panels operate less efficiently than monocrystalline panels because the melted fragments of silicon afford less room for the electrons to move around. Polycrystalline panels generally have an efficiency rating of between 13% and 16%.

Q: Why are pipes in solar panels painted black?

A: To increase the absorption of heat energy by the water, the copper tubes are painted with black color.

Q: Is it better to have solar panels flat or angled?

A: The perfect angle: A common rule of thumb is that solar panels are most productive when they’re installed at an angle to match the local latitude.

Q: Can a solar panel overheat?

A: The main electrical consequence of your solar panels getting too hot is a drop in their power output and, if their temperature rises above 85°C, they may stop working. Even then, most will continue functioning, but there will be a significant impact on their performance.

Q: What is the average cost of polycrystalline solar panels?

A: Solar panel costs by type

The average cost for these panels is between $1 and $1.50 per watt, but prices may differ depending on location. Polycrystalline panels are popular for homeowners on a budget. They have a moderate efficiency rate ranging from 15% to 17%. Their cost is between 90 cents and $1 per watt.

Q: Are poly solar panels good?

A: Whether monocrystalline or polycrystalline panels are better for your home depends on your roof space, budget, and personal preference. Mono panels are more efficient and require less space but cost more. Poly solar panels are less efficient and need more roof space but are more affordable.

Q: What are polycrystalline solar panels made of?

A: Polycrystalline also known as multi-crystalline or many-crystal solar panels are also made from pure silicon. However, unlike monocrystalline, they are made from many different silicon fragments instead of a single pure ingot.

Q: Do I need a gap between solar panels?

A: Also, remember that you might not be able to fit as many panels on a flat roof as you would on a pitched roof. To avoid shading from the raised structure of the panels, there needs to be about a metre gap between each row of solar panels on a flat roof.

As one of the most professional poly solar panel manufacturers in China, we’re featured by quality products and good service. Please rest assured to buy customized poly solar panel made in China here from our factory.